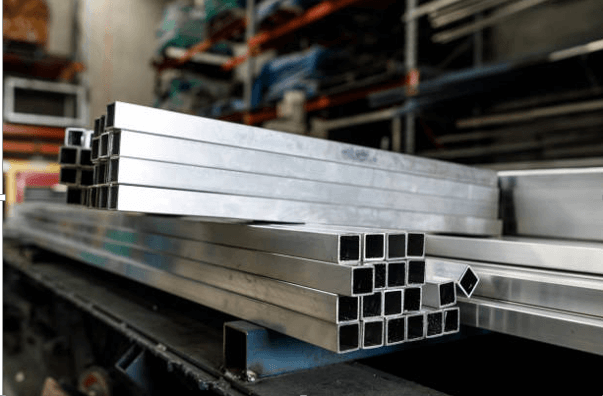

Cost vs Performance: How 4130 Rectangular Tubing Delivers Value in Structural Projects

Budget constraints often push engineering teams toward opting for cheaper tubing options, but the decision can backfire quickly. When structural failures occur or maintenance costs spiral, the initial savings vanish in thin air. Smart procurement teams look past the price tag to evaluate what materials can actually cost over their service life. This approach reveals hidden expenses that cheaper alternatives often carry.

Specifying 4130 rectangular tubing for demanding structural applications changes the cost conversation entirely. This chromium-molybdenum alloy steel delivers mechanical properties that outperform common carbon steel options, which matters when you calculate long-term ownership expenses. The material combines high tensile strength with excellent fatigue resistance, creating a performance profile that reduces failure risk in critical load-bearing structures. Project managers who track total ownership costs recognize this value proposition quickly.

Breaking Down Real Ownership Expenses

Material Price Versus Lifecycle Value: The upfront cost difference between grade 4130 and standard carbon steel tubing creates sticker shock for some buyers. You might pay 40 to 60 percent more per linear foot compared to basic structural steel options. That gap narrows fast when you account for reduced replacement frequency and lower maintenance requirements. Structures built with inferior materials often need reinforcement or replacement within five to seven years under demanding conditions.

Fabrication and Installation Efficiency: Welding procedures for 4130 require specific techniques, but the material’s consistent chemistry produces reliable joints that hold up under stress. Fabricators who understand proper heat treatment can create connections that match or exceed base material strength. This predictability reduces rework and costly on-site corrections that plague projects using inconsistent material grades. Your installation timeline stays on track when welds perform as expected.

Service Life Extension Benefits: Structures exposed to dynamic loading, vibration, or thermal cycling gain years of reliable operation with 4130 tubing. The alloy’s resistance to fatigue cracking means components maintain structural integrity longer than alternatives that develop stress fractures. Projects in mining, material handling, and heavy equipment benefit from this durability. Downtime costs dwarf material savings when critical structures fail unexpectedly during production runs.

Performance Advantages That Reduce Hidden Costs

Load-Bearing Capacity Per Pound: Design engineers can often reduce wall thickness when specifying 4130 due to its superior yield strength compared to mild steel alternatives. This weight reduction translates to lower shipping costs, easier handling during installation, and reduced foundation requirements. The compounding savings add up across large projects where every pound matters. Lighter structures also mean lower labor costs during assembly and modification work.

Maintenance Interval Extensions: Inspection and maintenance schedules stretch out when your structural components resist deformation and cracking. Teams using 4130 in chassis, frames, and support structures report maintenance intervals that double or triple those of carbon steel equivalents. You spend less on labor, equipment downtime, and replacement parts. Production managers appreciate the predictability this reliability brings to scheduling and budget planning.

Failure Risk Mitigation: Catastrophic structural failures carry costs that extend beyond material replacement. Lost production, safety incidents, regulatory scrutiny, and reputation damage create expenses that eclipse any upfront savings. Premium materials like 4130 reduce these risks substantially in applications where failure consequences are severe. Risk assessment teams recognize this value when evaluating material specifications for critical infrastructure.

See also: How Digital Transformation Impacts Business

Comparing Alternatives With Honest Math

Standard Carbon Steel Limitations: Basic structural tubing costs less initially, but performance gaps emerge under real operating conditions. Carbon steel fatigues faster, corrodes more readily in certain environments, and offers lower strength-to-weight ratios. These limitations force design compromises that add weight, bulk, and material volume to achieve required performance. Your total material costs often end up higher despite the lower per-pound price.

Stainless Steel Overkill: Some specifications default to stainless steel for corrosion resistance without considering whether the premium is justified. In many structural applications, 4130 delivers adequate environmental resistance at substantially lower cost than austenitic stainless grades. Surface treatments can enhance corrosion protection when needed. Matching material capabilities to actual requirements prevents overspending on unnecessary performance margins.

Performance Testing Validates Claims: Independent testing demonstrates 4130’s advantages across multiple failure modes:

- Tensile strength typically ranges from 90,000 to 120,000 PSI depending on heat treatment, compared to 60,000 to 80,000 PSI for common carbon steels.

- Fatigue life under cyclic loading extends 2 to 3 times longer than equivalent mild steel sections under identical stress conditions.

- Impact resistance remains consistent across temperature ranges where carbon steel becomes brittle, reducing cold-weather failure risks.

- Weldability ratings indicate good to excellent performance when proper procedures and filler materials are used during fabrication.

Procurement Strategies for Value Maximization

Volume Planning Reduces Unit Costs: Purchasing 4130 in production quantities rather than small lots significantly improves pricing. Establishing relationships with reliable suppliers who stock common sizes reduces lead times and minimizes emergency purchases at premium rates. Your procurement team can negotiate better terms when committing to consistent volumes over time. Planning ahead pays dividends that offset the material’s higher base cost.

Specification Precision Prevents Waste: Ordering exact dimensions needed for your application eliminates expensive secondary machining operations. Custom length cuts, specific wall thicknesses, and precise tolerances reduce fabrication labor and material waste. Working with suppliers who offer value-added services streamlines your supply chain. Time saved in fabrication shops translates directly to project cost reductions.

Making the Investment Work

Choosing premium structural materials like 4130 rectangular tubing demands a shift from purchase price thinking to total value analysis. The material delivers measurable returns through extended service life, reduced maintenance, and lower failure risk. Engineering and procurement teams who track these factors make confident specifications that withstand budget scrutiny. Start evaluating your structural tubing requirements with lifetime cost models that capture the full picture of material performance and reliability.